LAMINATED GLASS

Offering a host of advantages Integral Seal’s Laminated Glass is the ideal option when designing for architectural applications large and small.

Designed form maximum clarity along with stability over a long period of time Coloured Interlayers offer a simple yet stunning option to any internal glass project. Permanently laminated between two panels of glass, the wide array of colours range from subtle blues and greens to vibrant bright reds and purples.

Because the film is laminated between panels the adhesion lasts far longer than regular stick on films, removing the chance of those unseemly peeling edges. Coloured Interlayers are manufactured from sustainable materials and maintain their impact resistance. They reach the all typical safety standards of Integral Seal’s regular EVA laminated glass panels.

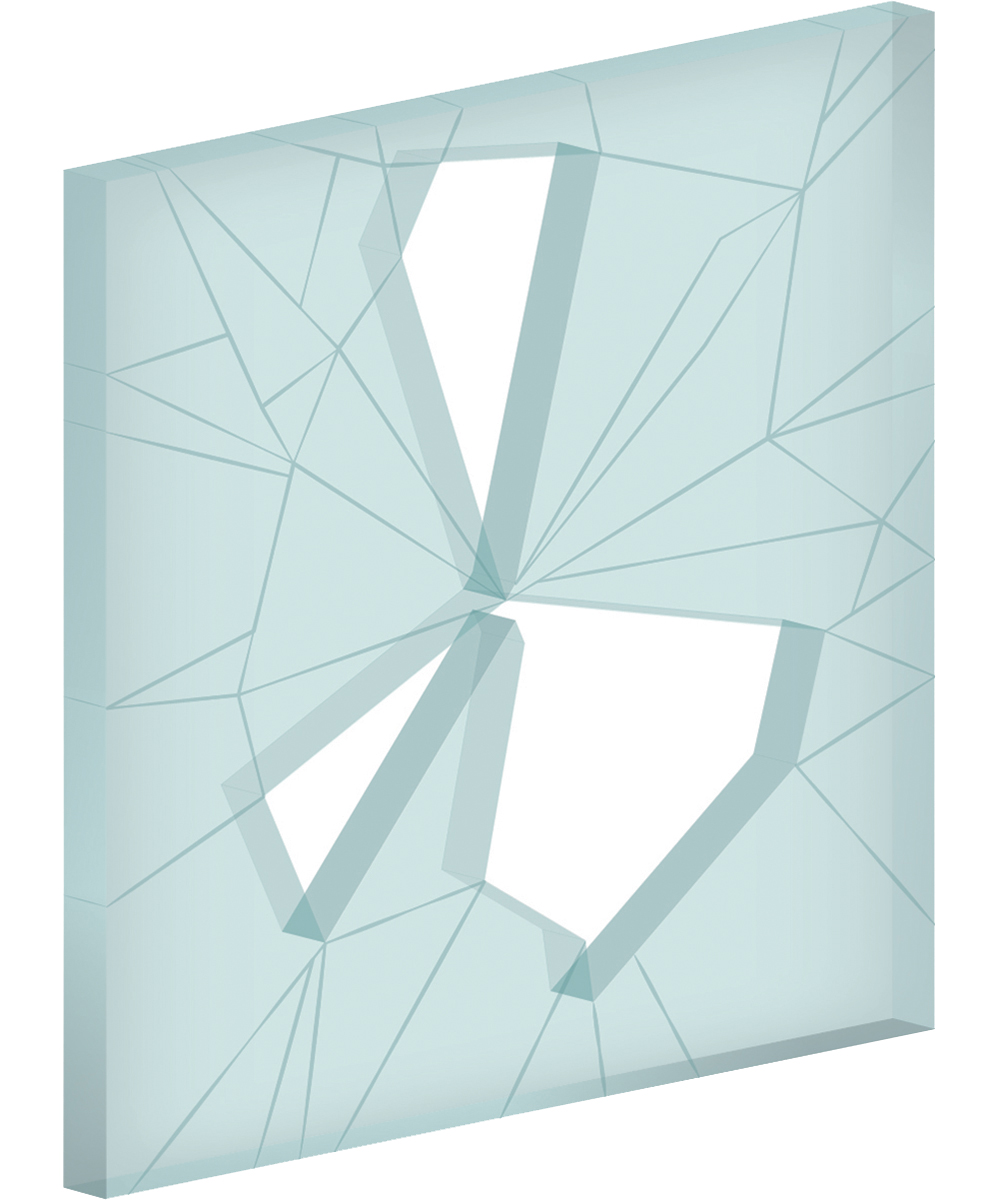

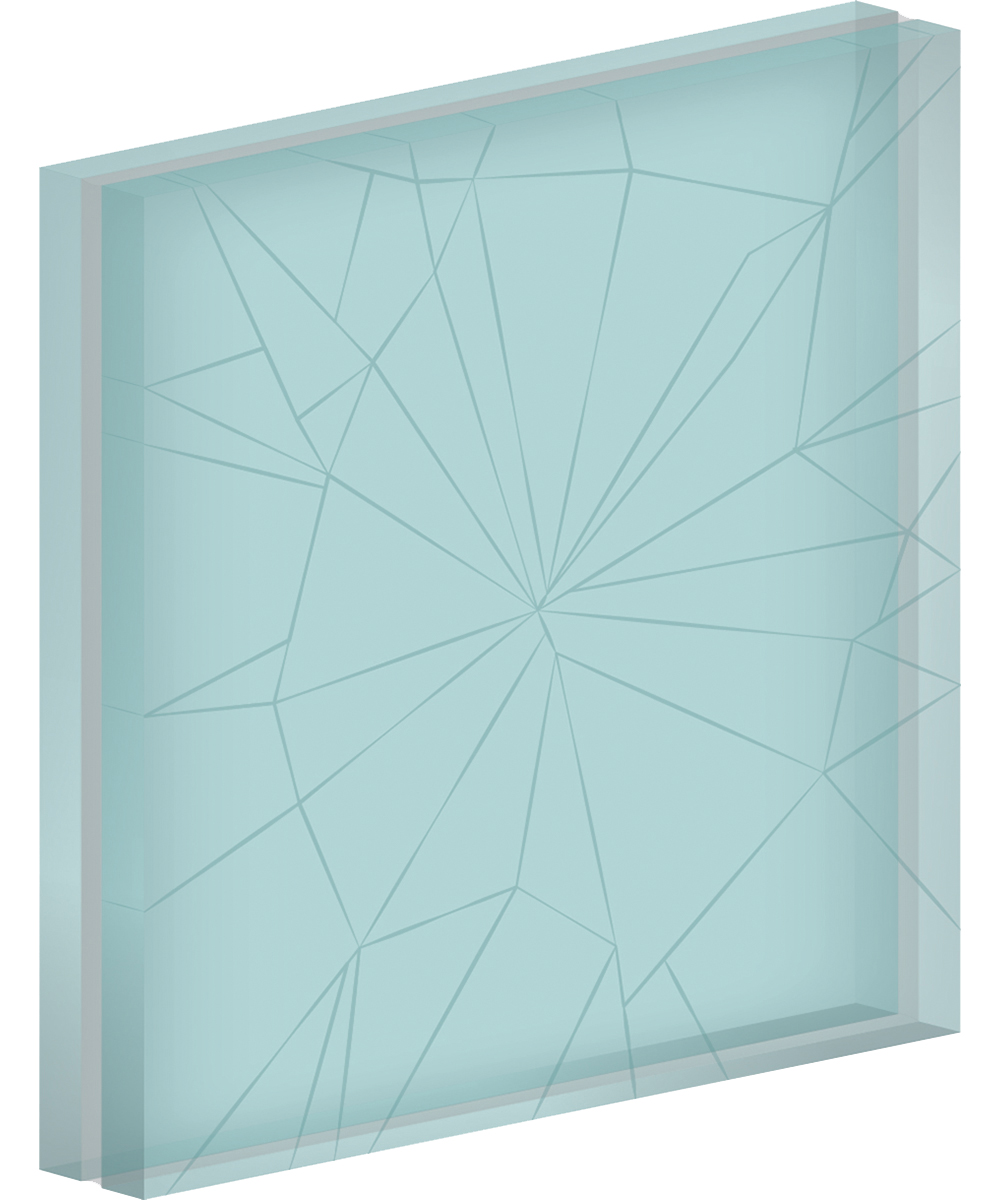

Glass Comparison

Broken Single Panel

Broken Laminated Panel

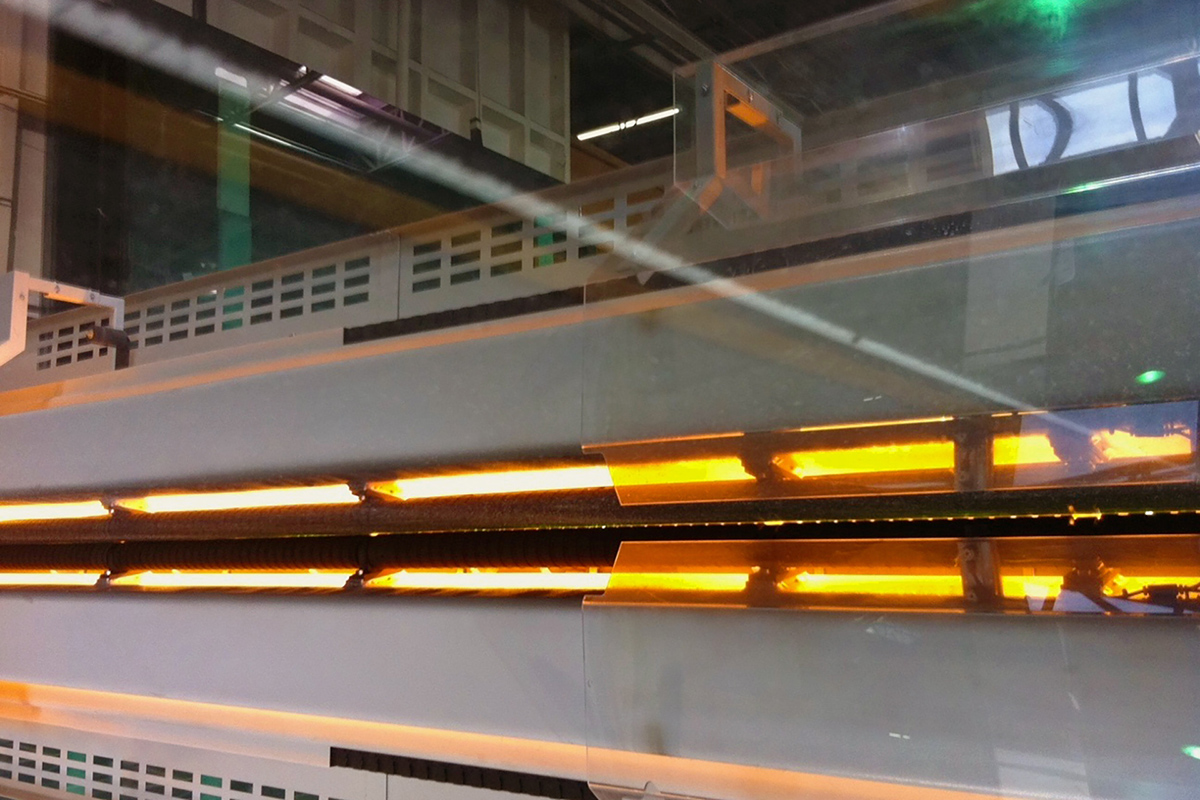

Another benefit to laminated panels is increasing the sound insulation rating of a glass window. Testing found significant improvements in sound attenuation compared to single monolithic glass panes of the same thickness. The benefits continue when laminating performance glass panels, creating a truly custom option for whatever the project may require. Integral Seal’s lamination line allows panels to be cut much faster and more efficient than by hand removing excess waste thanks to the computerized optimization software. The process is carried out by our specialised production equipment which scores, cuts, heats and trims the interlayer all at the push of a button, removing human error and giving a far more precise finished product.